Preventative Corrosion Solutions

NashGuard

An innovative and unique coating technology

Product Features.

- Non-Toxic, Non-flammable, Environmentally friendly, Single Component Coating

- Brush and Roller applied

- Can be made to any BS or RAL colour

- Can be applied to all Metals, Concrete, Plastics

- Repair process (if required) is simple and needs no special equipment. NashGuard will amalgamate into itself, so there are no delamination concerns after repair.

- No limit to over coating time

- Quick Curing

- The coating removes oxidation form the surface, removing CUI concerns and it will not leach oil or unwanted matter onto the insulation. Making it an ideal coating under insulation

- Environmentally friendly. Any cured removed or discarded material, can be collected and recycled by manufacturer.

Key Benefits.

- No impact on Simultaneous Operations

- Long life performance against corrosion and extreme atmospheric conditions (up to 10 years)

- Easy removal process if required

- no special equipment required such as Compressors, Special PPE, Airlines, Blasting Equipment, mechanical preparation equipment.

- Achieve increased m2 with minimal manpower

What makes Nash Guard different?

What makes Nash Guard different?

Nash Guard is not just a “coating”

This is important, NashGuard isn’t just a “coating”, it is a complete anti-corrosion system, designed and developed to arrest corrosion on aging assets and prevent it coming back, and protect new assets to eliminate any potential for corrosion.

Contains Corrosion eliminators and inhibitors

These corrosion eliminators and inhibitors within the different elements of the system, actively remove and eliminate “rust” from the asset, penetrating deeply into scabs or corrosion blisters, arresting the oxidation processes, eradicating corrosion and preventing further decay.

Application onto a “lightly” prepared surface

This elimination of rust, oxidation and corrosion, removes the normal requirement to blast clean a surface prior to coating, allowing NashGuard coating to be applied directly onto a “lightly” prepared surface. By lightly, we mean hand wire brush and removal of loose contaminants and oil/grease.

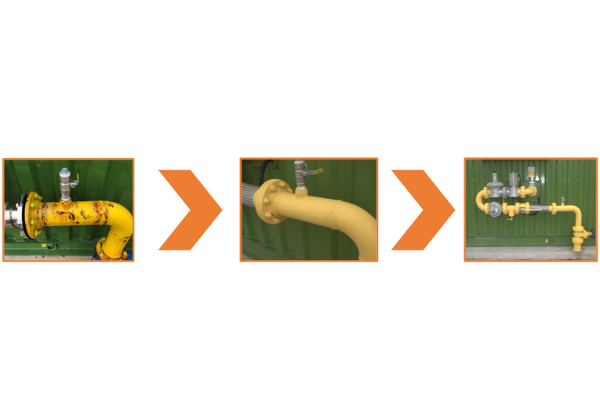

Pipeline and Flange Inspections

As the coating works as an encapsulation, the system can be removed at any time by cutting into the system and peeling back the coating. This allows for flange inspections or removal of bolts to allow opening. After works completed, NashGuard system can be reapplied and the coating will amalgamate into itself, giving full protection once again.

NG-OE - NashGuard Oxide Eliminator

What and Why?

There will be instances where you need to treat the surfaced of the substrate, to push moisture out of scabs and to eliminate and rust on a surface.

Application and protection is a very straightforward process

- Note: NG-OE is designed, developed and produced by Nash Guard. Other “off the shelf” rust converter products have too strong an acid for industrial paint application and WILL damage the original coating and the pipe wall.

- After half an hour, clean the surface and wipe off with a rag – we clean the surface only to get rid of the moisture and dirt that will come out of the scabs

- On critical pipework, where conventional clean and repair methods may cause issues, use NG-OE to clean out the blisters and apply NG 250 directly over blisters, no need to remove, and actively arrest further corrosion protecting the pipeline

Corr-Ze

Ultimately Clean Metal in Minutes stop flash rust and prevent corrosion under coatings well into the future. Apply Corr-Ze™ to metal assets or components to remove impurities in one step.

Lets take a look at the Corr-Ze surface preparation products at work.

Corr-Ze™ Benefits:

- 1-step application

- Leaves pH neutral surface

- Fast-drying

- Biodegradable

- Will not leave a film or residue at any concentration

- Improves coating adhesion

- Significantly prevents flash rust

- Water-base

- Non-toxic

- Non-flammable

- No need to coat the same day

- Will not damage blasting equipment (Thompson valves or wet end pump ceramic rods and dynamic seals)